Density reduction is the one of the most frequent pursuits of the XPS producing companies. There are numerous advantages in lowering the weight per volume of foam produced such as:

However, the biggest pre-requisite for a successful XPS density decrease is to maintain the set of properties of the foam produced and especially:

Another critical aspect is:

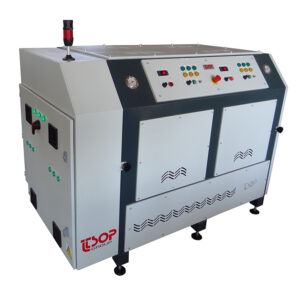

TSOP’s team of experienced Process and Mechanical engineers created a unique post expansion tunnel while keeping their focus in all the above. It is designed and built in a way that gives the absolute control of the conditions that prevail inside the tunnel to the operator. This gives a more uniform and stable result that is within the set of product properties that have been pre-defined by each producer. This is done with absolute safety and with the reduction of overall flammability as well as fire risks during the process of XPS foam expansion.

Furthermore, the post expansion tunnel system is:

All the above come into a fully integrated, autonomous system that does not affect the rest of the mechanical equipment or the chemical processes that you already use.

And most importantly, our experienced team will support you all the way from the installation and training until the successful operation and the achievement of the targets.